How to Calculate Carbon (CO2) Emissions from Your Supply Chain

For most physical product companies, supply chains represent one of the largest sources of greenhouse gas (GHG) emissions and environmental impact. In industries ranging from apparel and consumer goods to electronics and food, thousands of companies are investing in supply chain transparency, supplier engagement, and carbon accounting efforts to calculate their Scope 3 emissions, achieve climate targets, and reduce business risk.

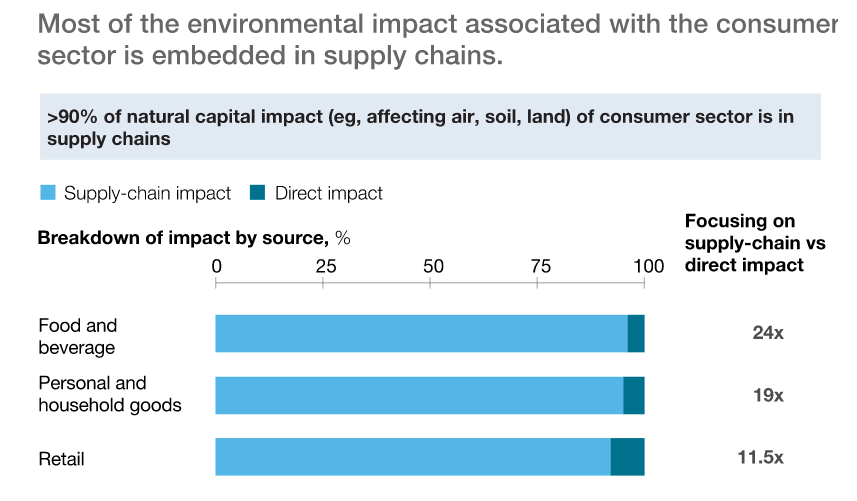

According to CDP and McKinsey, a company’s indirect emissions, including supply chain emissions, are, on average, 5 to 25 times higher than its direct emissions. So how should finance, supply chain, and sustainability teams approach supply chain carbon calculations, emissions reduction, and reporting?

Source: McKinsey

What are Supply Chain Emissions? A Definition

Definitions are extremely important in carbon accounting, and how to categorize supply chain emissions can be confusing even for experienced sustainability professionals. So before we start explaining how to calculate emissions across our supply chain, let's define what we need to include in our calculation.

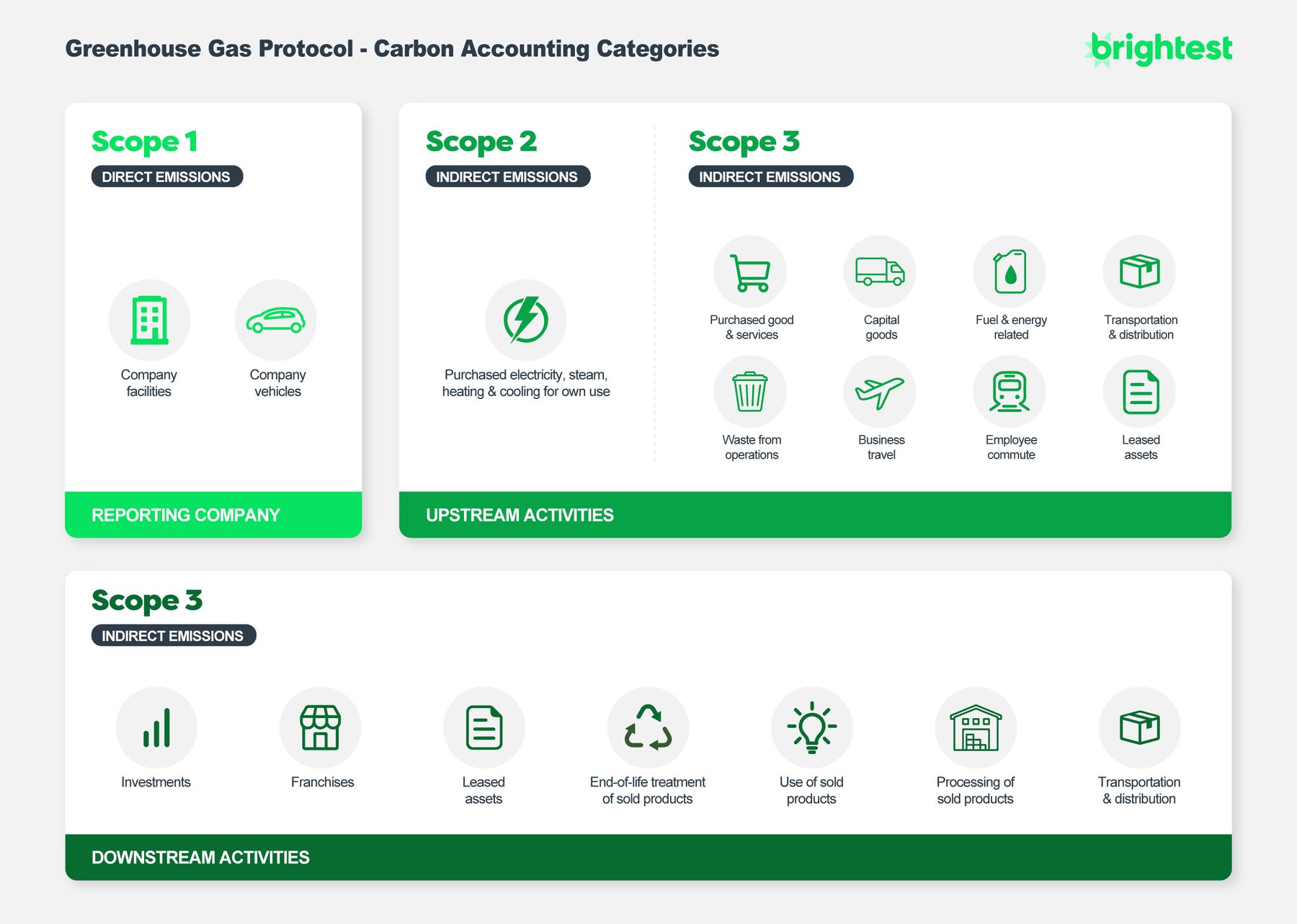

In carbon accounting terms, a company has an "upstream" and a "downstream" supply chain. Your upstream supply chain is the value chain that creates your products, including:

- Purchased goods and services - The extraction, production, and transportation of materials and services that go into your products

- Capital goods - The extraction, production, and transportation of capital goods purchased or acquired by your business. Capital goods can include machinery, equipment, vehicles, and tools that are used to make finished goods

- Upstream transportation and distribution - Transportation of goods and materials in vehicles not owned or controlled by your company

- Upstream leased assets - Leased assets from your upstream supply chain, like a rented factory or facility

- Waste - Waste generated from operations, including supply chain waste

- Business travel - Emissions from travel by your company's employees during the normal course of business

- Employee commuting - Emissions from travel by your company's employees going to and from work

By comparison, your downstream supply chain is your products going from your business to customers, all the way to the end of the product's lifecycle. This includes:

- Downstream transportation and distribution - Transportation of goods and materials in vehicles not owned or controlled by your company and not accounted for in your upstream supply chain

- Processing of sold products - Processing of any intermediate products sold

- End-of-life treatment of sold products - Waste disposal and treatment of products sold by your company at the end of their life

- Downstream leased assets - Leased downstream assets, like a rented warehouse or distribution center

- Franchises - Emissions from any franchises, if applicable

- Investments - Any investment-related, indirect emissions in a company's supply chain

Together, the sum of your upstream emissions plus your downstream emissions equals the total carbon footprint of your supply chain. The U.S. Environmental Protection Agency (EPA) and Greenhouse Gas Protocol - the gold standard for carbon accounting guidance - define this as your company's Scope 3 emissions. By comparison, Scope 1 and 2 emissions come from your company's direct operations - not your supply chain.

Carbon Accounting of Supply Chain Emissions

If you're familiar with financial accounting, which adds up income and expenses into a budget, carbon accounting works in a similar way. An organization's emissions are its carbon inventory, which can be reduced or netted against carbon improvements or offsets.

The established, global accounting unit for emissions is the greenhouse gas carbon dioxide (CO2), and "carbon equivalents" (CO2e) - the sum of carbon plus other emissions like methane converted into carbon. To calculate supply chain Scope 3 emissions, count up all the upstream and downstream emissions the supply chain generates, convert everything into carbon equivalents using the right emissions factors, then add them together.

Upstream CO2e Emissions + Downstream CO2e Emissions = Total Scope 3 GHG Emissions

That's supply chain carbon accounting.

Supply Chain Carbon Accounting Boundaries

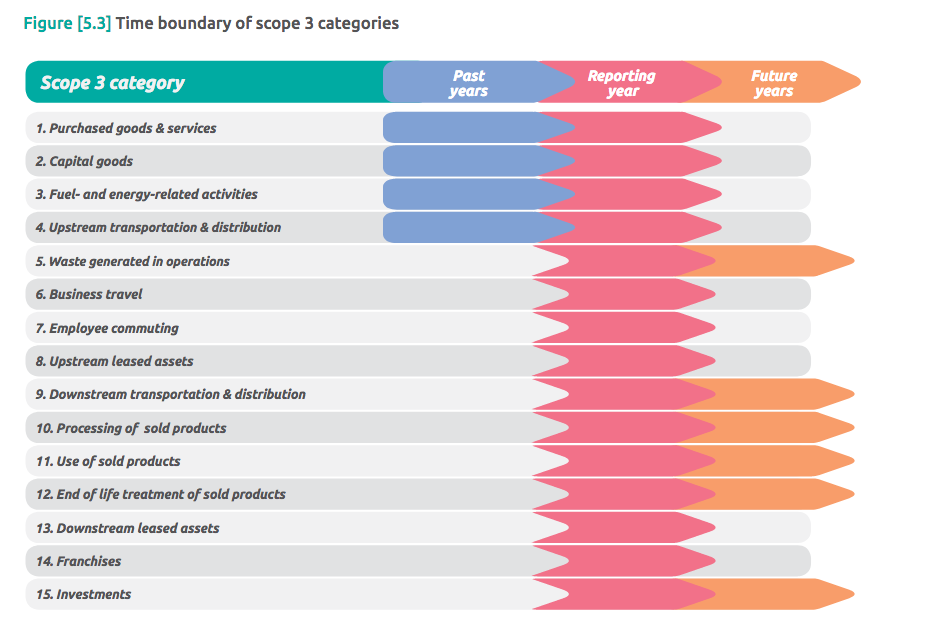

One other important concept to understand in supply chain emissions measurement is "boundaries." Boundaries define the timing and relevance of your carbon accounting focus.

Boundaries matter because for some scope 3 categories like driving a delivery truck, emissions occur as the activity happens - but in other cases, they don't. When a truck drives, it burns fuel which produces CO2 pollution. So if we're calculating carbon from delivery trucks in our supply chain, we count all the truck trips that occur in the same year we're doing the calculation.

On the other hand, let's say we're an automotive company that sells trucks. Our customer doesn't buy our truck and drive it for one year. In this case, we need to account for the entire emissions lifecycle of the product. If we sell 1,000 trucks, and a customer, on average, drives our trucks for 10 years, we need to account for 10 years of carbon emissions from our trucks being driven.

For each Scope 3 emissions category, make sure to use the correct time boundary for your carbon calculation:

A second boundary to keep in mind for supply chains is the value chain step boundary. Most upstream supply chains are divided into Tiers based on the order that they operate, like links in a chain. For example:

- Tier 4 Supplier - Raw material extraction, the start of the upstream supply chain ↓

- Tier 3 Supplier - Raw material processing ↓

- Tier 2 Supplier - Unfinished goods processing ↓

- Tier 1 Supplier - Finished goods manufacturing ↓

- Brand A - Sources and purchases finished goods from their Tier 1 suppliers at the end of the upstream supply chain

If we work at Brand A and are assigned with calculating supply chain emissions, there are different boundary approaches we might apply for what to count and what to exclude. The most basic or "loosest" carbon calculation would be to only include emissions from Tier 1 suppliers. A more thorough and comprehensive supply chain assessment will count Tier 2 suppliers, as well as Tier 1. This Tier 1 + Tier 2 supplier carbon accounting approach is recommended for science-based emissions targets (SBTs), as well as by third-party standards organizations like the Sustainable Apparel Coalition.

Brand A could take their supply chain emissions assessment even further and include Tier 3 and Tier 4 suppliers (and some organizations do), but most would consider Tier 1 + Tier 2 to be a sufficient value chain boundary for supply chain emissions. Given the complex nature of global supply chains, some companies may not even have visibility into their Tier 3 and Tier 4 suppliers.

How to Calculate Supply Chain Emissions

Now that we have a clearer understanding on what our supply chain calculation should include, let's walk through the ways you can perform your carbon calculation. The right supply chain measurement approach for you and your company will primarily depend on what data you have, as well as the carbon accounting resources available to you.

The first method is a spend-based carbon accounting estimate. Spend-based supply chain carbon accounting takes the financial value of a purchased good or service and multiplies it by an emission factor – the amount of emissions produced per unit or monetary value of the goods – to calculate an estimate of your emissions.

There's no universal source of emissions factor (although we've been working hard to collect and build them into our software; we hope to open source a directory of emissons factors in the near future). The emissions factors you choose will need to come from government agencies, academic research, company reports, and third party standards organizations.

To perform a spend-based emisisons calculation you need three data sources: your purchases, your suppliers, and the corresponding emission factors. This data will typically come from your accounting team, who can export it from your company's accounting system.

The spend-based method works best if the most accurate data you have is financial purchasing order or similar data. For example, say you don't have direct supplier data, but you do know your company spent $1 million dollars ordering goods and services from your Tier 1 suppliers in your reporting year. The spend-based method calculates the value or number of units you purchased, multiplied by an industry average emissions factor for that product.

Since spend-based emissions calculations use industry averages, a spend-based estimate will be less accurate. We might estimate the carbon footprint of a shirt, but we aren't accounting for environmental differences between a shirt made of cotton, silk, polyester, or recycled scrap fabrics.

A second calculation method is an average data carbon accounting estimate. This method is similar to the spend-based method, but instead of using financial data relies on material weight data. If our company's clothing is made of X tons of cotton, multiply the weight times the appropriate emissions factor for the material. Like the spend-based method, average data carbon accounting also suffers accuracy issues due to the use of averages.

The most accurate form of supply chain carbon accounting is the supplier-specific method. Supplier-specific carbon accounting collects product-level cradle-to-gate GHG data from each supplier using sustainability surveys and data collection workflows.

Supplier-specific emissions data is a form of activity-based estimation. If we work with 10 suppliers, each one gets their electricity from a local power utility, and they share their monthly utility bills, we can convert that energy in kilowatt hours (kWh) or megawatt hours (MWh) to carbon. This same general process can be applied to water usage, transportation vehicles, shipping, and all the different activities and steps in your supply chain. Gather the activity data, identify the right emissions factor, and convert the activity to CO2e.

Gathering this data can be very time-consuming, and there may be gaps. Some suppliers may not know their emissions data in depth. A hybrid emissions calculation approach uses supplier-specific and activity-based data wherever possible, then fills in the gaps with industry averages. This hybrid approach can still be fairly precise, or at least much more so than a spend-based or average data-based emissions calculation.

Improving Your Supply Chain Transparency and Emissions Accounting Maturity

Every supply chain's different, and every company starts at a different point in their sustainability journey. If you’re calculating your supply chain’s carbon footprint for the first time and have limited data, you may want to begin with a spend-based estimate. As your resources, capabilities, and supplier engagement efforts progress, you can improve your calculation accuracy with more direct supplier data.

Software can also make the process of collecting and calculating supply chain emissions much easier. For example, Brightest includes helpful sustainability automation features like schedulable supplier surveys, automatic data mapping, automated carbon calculators, encoded emissions factors, and other benefits to free up your time, increase carbon accounting accuracy, and help improve the sustainability of your supply chain.

An example of Brightest's sustainability software auto-converting supplier water usage into carbon equivalents

You can also track, measure, and visualize your company's climate footprint over time, including Scope 1, 2, and 3 GHG emissions, plus quickly turn your insights and data into sustainability and ESG reporting.

Whichever method you choose, remember supply chain transparency and carbon accounting takes investment, but also presents us with a valuable opportunity to improve our company's climate performance and reduce risk. If we can be helpful to you or your organization’s sustainability journey, please be in touch.