Sustainable Supplier and Vendor Engagement

From Apple and Adidas to Walmart and Whole Foods, companies around the world are actively taking steps to engage their vendors and suppliers more closely on sustainability and ESG matters. Issues like forced labor in Xinjiang and worsening climate change continue to elevate the importance of supply chain traceability, transparency, and sustainability in 2022.

But, unlike internal sustainability initiatives, vendors and suppliers have a different relationship - and accountability level - to your company. While your top Tier 1 suppliers and vendors may play a strategic, long-standing role within your supply chain, many others may not be engaged in a close. transparent relationship. When a major percentage of your business' emissions and environmental impacts reside in your supply chain, but those organizations don't work for you directly, what are the best ways to engage them on sustainability?

Our top recommendations are:

- Map and prioritize your suppliers

- Supplier sustainability is led by transparent communications and empathy

- Start with a baseline sustainability or ESG survey if you haven't already done this

- Ensure policies and procurement standards reflect your sustainability criteria

- Create collaborative scorecards and action items

- Find the right time (and process) forScope 3 emissions measurement

- Manage supplier and vendor sustainability data with a quality system

- Partner on long-term progress and impact

Map and Prioritize Your Suppliers

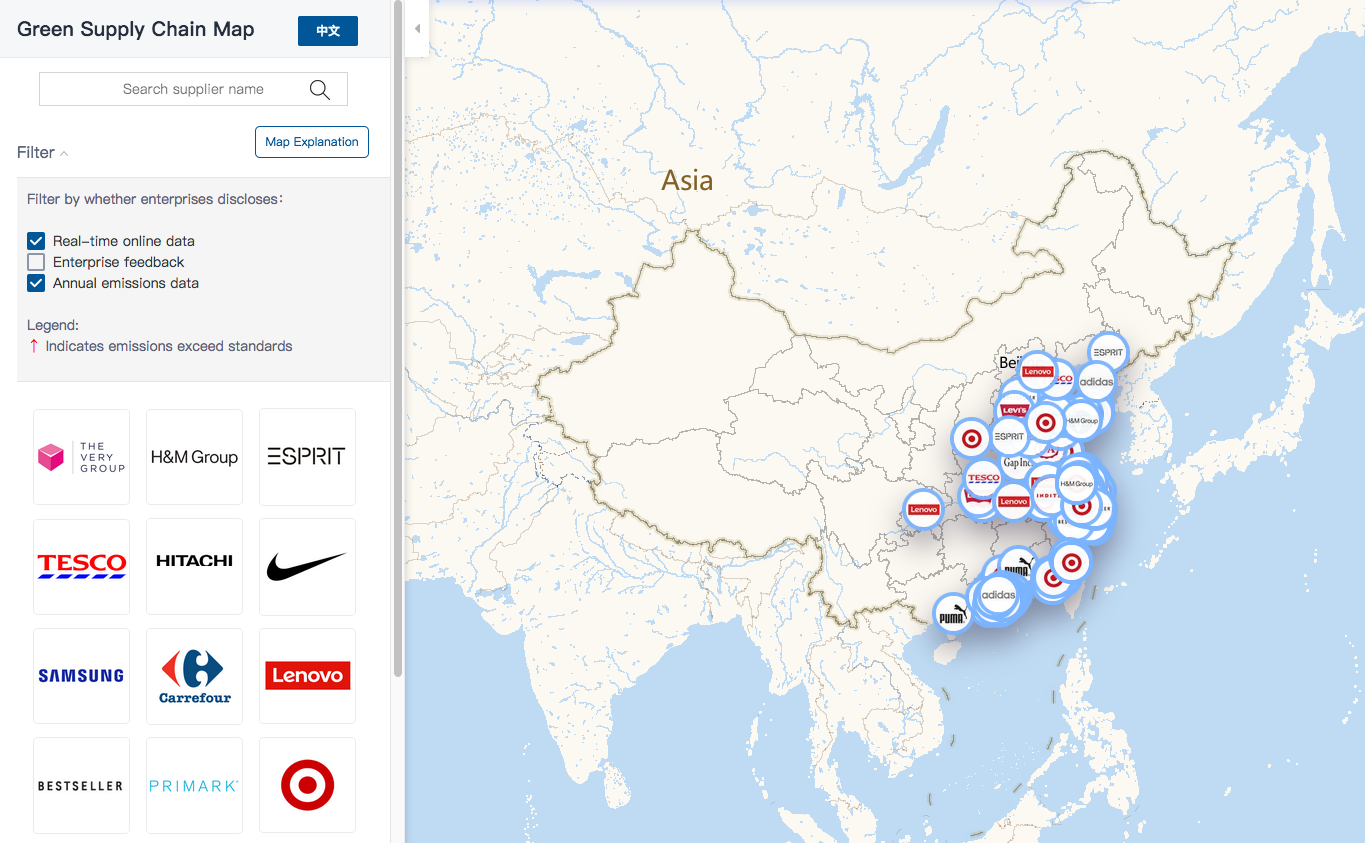

While most organizations already have a clear picture of their Tier 1 and Tier 2 suppliers, it's important to start with a good data baseline on your supply chain. Who are your largest and most strategic suppliers? Who have you worked with the longest? Who's responsible for sustainability and environmental compliance at each supplier? What social compliance, ESG, or sustainability risk assessments and audits have you conducted so far (if any)?

Whether your organization works with dozens of suppliers and vendors or thousands, value chain engagement on sustainability is a prioritization exercise, and also a diplomatic one. Start with your most important relationships, build capacity, momentum, and proofs-of-concept with those top partners, then scale those best practices to your other relationships through programs, policies, and standards.

Supplier Sustainability is Led by Transparent Communications and Empathy

The larger your procurement and sourcing operations, the more influence you'll likely have among your suppliers. Nonetheless, if you're earlier in your supply chain sustainability improvement journey, it's best to transparently reach out to your top suppliers and strategic vendors to clearly explain:

- Why you're taking action on sustainability and ESG in the supply chain

- Why these actions are so important to your business

- Why these actions will also benefit the supplier (there's a good chance their other customers are also actively engaging them on sustainability and ESG topics)

- The priorities where you specifically need additional engagement from the supplier (and why)

If necessary, engage senior leadership in these communication efforts. Will this message carry more weight if it comes from your Chief Supply Chain Officer? Or even your CEO? Similarly, if your supplier point-of-contact is the environmental compliance manager, do more senior stakeholders at the supplier also need to be engaged in this conversation?

In our experience working with global suppliers on sustainability and ESG, most suppliers genuinely want to support your sustainability efforts, but are also under-resourced and often under-educated in these areas. Most suppliers are used to filling out sustainability surveys, but not necessarily engaging directly on sustainable sourcing plans or environmental efficiency projects.

The more you can find common ground with the supplier and communicate why sustainability is in their best interest for the long-term growth, health, and stability of their business, the easier subsequent engagement steps will become.

Start With a Baseline Sustainability or ESG Survey (If You Haven't Already Done This)

Meet with your priority Tier 1 suppliers about conducting a supplier sustainability survey to gather data and insights on their facilities, business practices, operations, and environmental footprints. Try to understand what they do and don't measure. Ask for evidence and verification documents. And educate them on why this information is important and how your organization will use the data.

Work on establishing a data and evidence-backed baseline for your top suppliers, and start to look for trends, patterns, and outliers. Have you benchmarked your suppliers vs. standards in your industry? Are there regional or country-specific trends? Do specific suppliers have much higher environmental intensity for their operations compared to peers? Are there suppliers who aren't tracking environmental metrics at all?

Eventually, you want to get to the point where you're regularly surveying all your suppliers, at least annually, to track performance improvement and monitor changes over time.

Need a unified system for supplier sustainability engagement?

Brightest helps hundreds of companies measure 3 emissions and collaborate with suppliers on top ESG indicators

Ensure Policies and Procurement Standards Reflect Your Sustainability Strategy

When you're engaging your suppliers and vendors on sustainability, your organization should be consistent on its policies and practices. Make sure sustainability, supply chain, sourcing, and procurement are all aligned and working off the same plan. Constructive steps here include:

- Make sure supplier sustainability and ESG metrics and criteria are being incorporated into sourcing and procurement decisions. Engage and educate procurement on your work and goals if they're not already up to speed and bought in

- Create or integrate sustainability requirements and standards into your supplier code of conduct, policies, and procurement contracts. Make sure suppliers sign off on these obligations. Publish your sustainable sourcing policy on your company's public website

- Develop sustainability and ESG-focused supplier training materials and communications (toolkits, webinars, online workshops) to educate partners on best practices

- Assign internal relationship leads for key suppliers. Treat your top strategic suppliers like key accounts

- Hold monthly or quarterly value chain meetings for key sustainability and supply chain stakeholders

Above all, support your suppliers in their sustainability journey with resources and incentives. Are there financing solutions that can help a supplier cover capital expenditures for sustainability improvements at their facility? Are there resource and knowledge-sharing opportunities? Will the supplier see increased order volumes or more order security from implementing verifiable sustainability improvements?

Be sure to engage and hold your suppliers and vendors accountable when they're not meeting your sustainability standards, but also help them see the benefit from investing their time and resources to meet your ESG program and purchasing criteria.

Create Collaborative Sustainability Scorecards and Supplier Action Items

Collaborative, transparent scorecards are a great way to engage your suppliers on sustainability and ESG. Use and review suppliers' scorecard performance in your annual review with them. Highlight success areas, action items, and risks in the context of your sustainability targets.

Quality supplier scorecard metrics and information to consider including are:

- Existence of supplier climate action plan, environmental management system (EMS), resources, staffing, and controls

- Supplier emissions

- % of energy from renewables

- Water usage

- Wastewater generated from opeartions

- Waste generated from opeartions

- Refrigerant usage

- Chemical usage (if applicable)

- Supplier sustainability initiatives, plans, and targets

Brightest's supply chain sustainability software platform provides collaborative, real-time ESG supplier scorecards

Find the Right Time (and Process) for Scope 3 Emissions Measurement

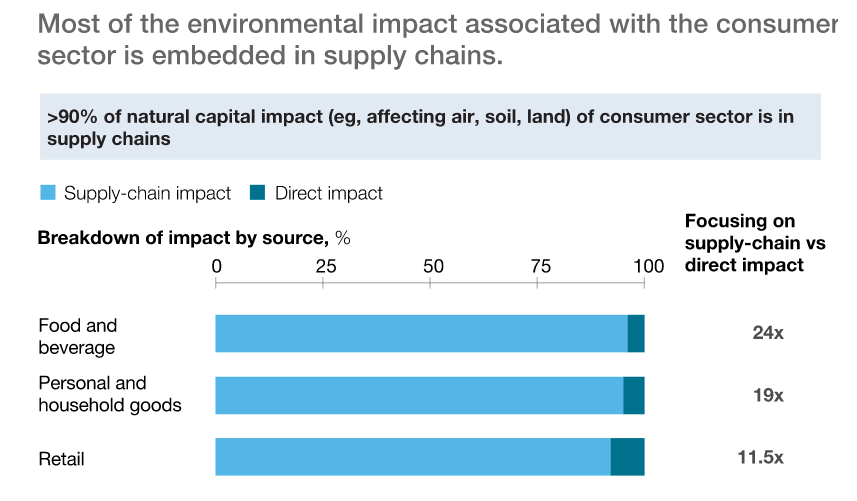

Understanding a supplier's greenhouse gas (GHG) emissions to factor them into your company's own Scope 1, 2 & 3 emissions reporting is high priority for many sustainability and supply chain teams in 2022. For those newer to carbon accounting, Scope 3 emissions are all of your business' "indirect" or value chain emissions, including vendors and suppliers.

For many companies - particularly ones with a physical product and global supply chain - Scope 3 emissions represent 60-90% or more of an organization's entire carbon footprint. And more and more investor, regulatory, and procurement questionnaires are asking companies to measure and disclose this type of GHG emissions data.

Source: McKinsey

Carbon accounting across your suppliers requires a holistic view of their operations and logistics, plus the ability to track, collect, and connect data at each step. It also involves ongoing use of procurement influence to shift suppliers in sustainable directions. By reducing partners’ Scope 1, 2 & 3 emissions, you limit and reduce your own company’s Scope 3 emissions.

Make sure as an organization you've laid the groundwork for these steps before you attempt to take this on.

- You you engaged and educated your suppliers on emissions measurement, how it works, and why it matters

- Do your suppliers have the capacity to track, measure, and manage this data?

- Have you completed enough supplier surveys and data collection to establish benchmarks and baselines?

- How much verification and audit work have you performed?

- Do you have the systems, processes, and data maturity to manage and keep track of supplier emissions data?

- Have you completed other more pressing internal sustainability priorities?

In a simple example, if your company works with 20 Tier 1 suppliers, each one needs to collect their electricity and other utility bills, and provide this documentation to you so you can convert that activity data into carbon. This same general process can be applied to chemicals, water, waste, transportation vehicles, shipping, and all the different activities and steps a supplier performs to get goods and materials to your company. Gather the activity data, identify the right emissions factor(s), and convert the activity to CO2e.

Gathering this data can be very time-consuming, particularly in complex, global suppliers, and there may be gaps. Some suppliers may not know their emissions data in depth. And your suppliers have their own suppliers and subcontractors. Use supplier-specific and activity-based data wherever possible, then fills in the gaps with industry averages and benchmarks. This hybrid approach can still be fairly precise, or at least much more so than a spend-based or average data-based emissions calculation.

Manage supplier and vendor sustainability data with a quality system

As the old saying goes, you can't improve what you can't see or don't have the ability to measure. If your company doesn't have a supplier and vendor database or tracking system, you need to work with IT and operations to purchase and set up. Many traditional supply chain management systems, ERPs, and databases aren't designed for sustainability reporting, scorecards, or ESG metrics. Make sure you take that into account, or use a dedicated supply chain carbon accounting system like Brightest.

Partner on Long-Term Progress and Impact

Like many areas of sustainability, supplier and vendor engagement requires a long-term outlook, and a tiered approach. Start by engaging your strategic Tier 1 suppliers and direct contract relationships. Build a shared business case, then meet with them and be transparent about your sustainability ambitions. Try to understand their perspective, and address any concerns, gaps, or needs.

Once you're consistently engaging your Tier 1 suppliers, work your way toward better understanding your Tier 2 suppliers and subcontractors. Your ultimate goal should be to develop a collaborative, transparent monitoring process where each supplier has clear action items and priorities, is aware of their "scorecard" performance, and is working in harmony with your organization's sustainability targets.

- Shared commitments

- Traceability and transparency

- Clear action plans

- Progress reporting

- Ongoing dialogue, collaboration, and communication

No matter what, you have to start somewhere, and we've seen organizations of all shapes and sizes (including some of the world's largest procurement organizations) increase their focus and investments in supply chain sustainability, traceability, and transparency in the past year. We expect this trend to continue and broaden, influencing more upstream suppliers and partners to comply with better ESG standards and labor practices.

Remember, this work is challenging, and most organizations are undertaking it right now. In a recent survey by The Sustainability Consortium, a non-profit dedicated to improving the sustainability of consumer products, less than 20% of the 1,700 respondents said they have a comprehensive view of their supply chains' sustainability performance. More than half reported being unable to determine top sustainability issues within their supply chain.

Despite these difficulties, in most industries, engaging your supply chain on sustainability is one of the most material paths to reducing your own organization's environmental footprint. Your supply chain is the foundation for your organization's sustainability performance and GHG emissions inventory, and it can't be overlooked.

Decarbonizing a global supply chain is complex, and requires internal capacity, resources, investment, and, most of all, time. But, when done well, supply chain leadership boosts everything from local community benefit to your firm's brand, reputation, operating financials, and investor consideration.