Supply Chain Due Diligence - Checklist, Key Questions & Best Practices

Supply chain due diligence is the process of evaluating and analyzing a company's supply chain to ensure it's socially responsible and sustainable

Because supply chains represent the full range of inputs, steps, activities, and companies involved in creating and delivering products and services to customers, supply chain due diligence typically examines the environmental, social, and governance (ESG) practices of suppliers, and assesses the risk of human rights abuses, environmental impacts, and other potential issues within a supply chain.

What Does 'Due Diligence' Mean in the Context of Supply Chains?

Due diligence means investigation, auditing, or research. Due diligence is a systematic risk management practice that companies, investors, and other organizations use to identify harmful business risks.

In supply chain management and sustainability, examples of supply chain due diligence include:

- Evaluating a supplier's financial stability: This can include reviewing financial statements, assessing a supplier's creditworthiness, and examining the supplier's track record in terms of paying its bills on time.

- Assessing a supplier's ethics and ethical practices: This can include evaluating a supplier's policies on labor practices, environmental responsibility, and compliance with laws and regulations.

- Due diligence on a supplier's human rights policies and practices: This might include supplier policies and practices toward fair wages, discrimination, child labor, forced labor, harassment and abuse, and safe and healthy working conditions

- Assessing a supplier's corporate governance and controls: Matters related to a supplier's ownership structure, controls, transparency, and ESG governance.

- Analyzing supply chain efficiency: This can include analyzing the flow of goods and materials through the supply chain, identifying bottlenecks or other inefficiencies, and implementing solutions to improve the efficiency of the supply chain.

- Due diligence on supply chain sustainability: This includes evaluating the environmental impact of the supply chain, including energy consumption, greenhouse gas emissions, water usage, and waste generation.

- Identifying potential supply chain risks and vulnerabilities: This includes assessing the risks associated with the supplier's business or location, including climate risk or political risk, as well as the risks associated with the supplier's business practices, such as the risk of fraud or corruption.

Supply chain due diligence should consider these risks at each step of the supplier chain, and for each specific supplier in a value chain.

Why is Supply Chain Due Diligence So Important?

Supply chain due diligence is important for a variety of reasons:

- It can spotlight and reduce harmful supply chain practices

- It can ensure compliance with international and local human rights and environmental laws

- It can protect a company's brand and reputation

- It can help minimize the risk of supply chain disruptions or other negative financial and non-financial impacts on the business

- It can help a company identify opportunities for improving the efficiency and sustainability of its supply chain

Entering 2023, supply chain due diligence has become a key compliance, risk management, and sustainable sourcing priority for companies around the world, particularly due to new supply chain due diligence laws in Germany and sustainability reporting requirements the European Union (EU).

For example, according to a report from the German government on business and human rights published in October 2021, 80% of mid-size and large companies in Germany today are not doing enough due diligence on their supply chains, which inspired the German government to institute their new supply chain due diligence laws, the "LkSG".

But supply chain due diligence isn't just a European regulatory trend, it's also picking up momentum in the United States and other countries as well. For example, in 2022 the U.S. government began enforcing the Uyghur Forced Labor Prevention Act, which prohibits goods, wares, articles, and merchandise mined, produced, or manufactured in the Xinjiang Uyghur Autonomous Region of the People’s Republic of China from being imported into the United States, due to the high prevalence of forced labor in Xinjiang.

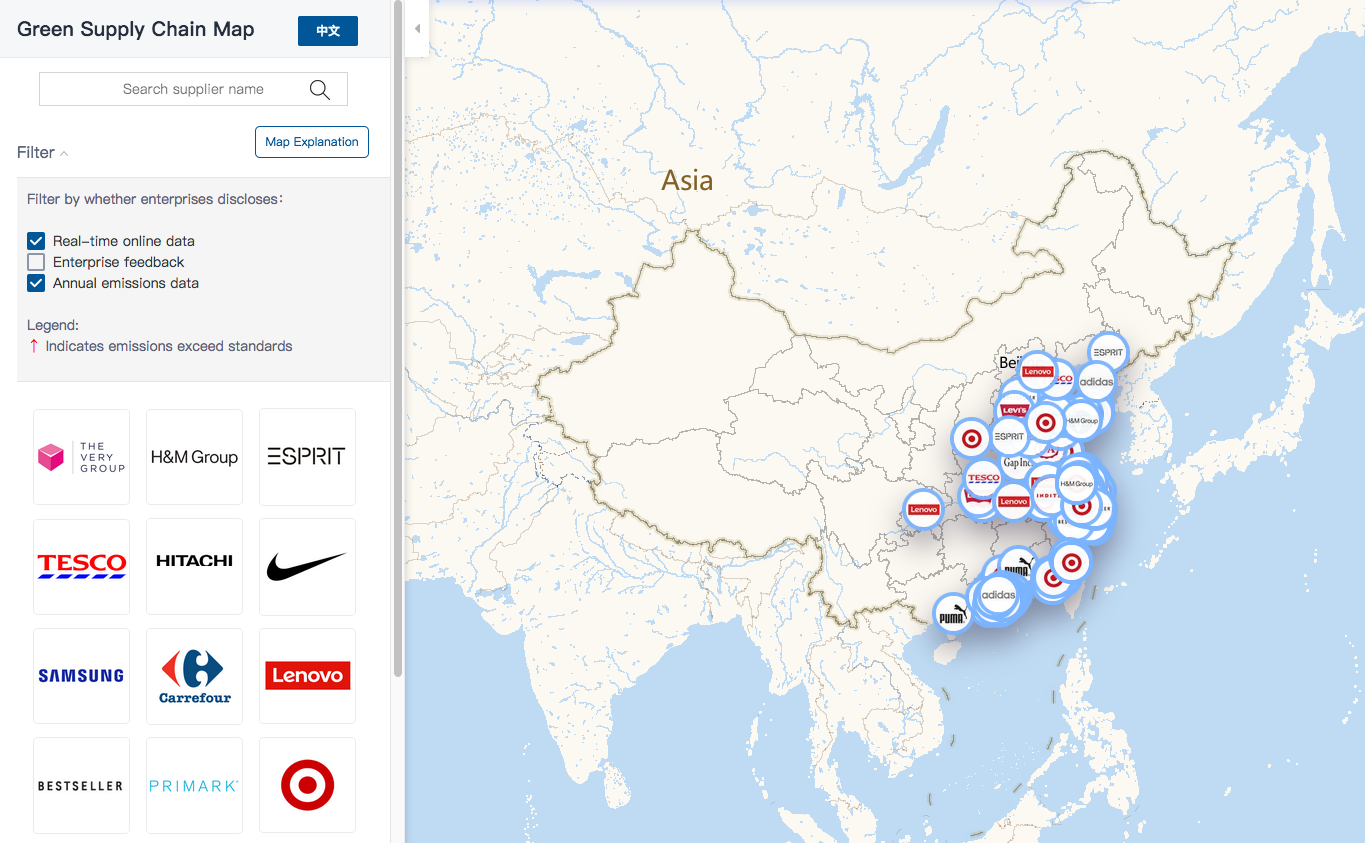

Supply chain sustainability due diligence mapping in China. Source: IPE

Supply Chain Due Diligence Checklist of Key Questions

After spending several years supporting organizations around the world in sustainable supply chain due diligence, we can affirmatively say there is no one-size-fits-all supply chain due diligence questionnaire or approach. Supply chain due diligence will be case-specific, and we've seen questionnaires ranging from a few dozen questions to several hundred.

However, that aside, there are some good first principles and best practices when it comes to designing a checklist of key due diligence questions and steps.

Best Practice #1: Gather Supply Chain Due Diligence Data from Multiple Sources

While supplier engagement and supply chain assessment surveys are an important due diligence input, they shouldn't be your only source of supply chain data. Gather data from governments, industry associations, NGOs, workers, and other unbiases, high-quality data sources to make sure you have a full 360° view of your supply chain.

Best Practice #2: Focus on Material Due Diligence Questions and Data

Example starter supply chain due diligence questions and question areas should include:

- Can you provide a copy of your company's most recent financial statements and business permits?

- What sustainability and human rights permits and certifications does your business or facility have?

- Do you have any outstanding legal, regulatory, or environmental issues that could impact your ability to supply goods or services to us?

- Do you have policies in place to ensure compliance with all relevant laws and regulations, including labor, environmental, and health and safety laws?

- Do you have processes in place to ensure that your own supply chain is sustainable and environmentally responsible? Is an experienced and accountable member of the management team responsible for these processes?

- Do you have policies in place to prevent discrimination, harassment, and abuse of employees?

- Do you have systems in place to prevent fraud, corruption, forced labor, child labor, and other unethical practices?

- Do you track and measure a key set of sustainability KPIs to assess your own ESG performance? Is that information properly managed and transparently disclosed?

- Do you have contingency plans in place in case of supply chain disruptions or other unforeseen events that could impact your ability to fulfill your obligations to us?

- Can you provide audits and assessments from other customers and trusted third parties who can attest to the quality of your goods or services and your reliability as a supplier?

Start by orienting your supplier due diligence assessments around those key topics and areas, then expand into more detail based on your specific reporting needs and due diligence goals.

Best Practice #3: Design Your Supply Chain Due Diligence Process Around Laws and Trusted Third Party Standards

If your organization is newer to supply chain due diligence, particularly related to sustainability, start by referencing existing due diligence regulations and standards. For example, Germany's new 2023 supply chain laws focus on preventing and reducing supply chain:

- Child labor

- Forced labor

- Modern slavery

- Wage discrimination

- Gender and ethnic discrimination and abuse

- Unlawful eviction

From a risk perspective, Germany's Supply Chain Due Diligence Act specifically highlights:

- Manufacturing, use, and handling of mercury products (according to the Minamata Convention)

- Production and use of banned chemicals (according to article 2, paragraph 1 of the Stockholm Convention on Persistent Organic Pollutants)

- Imports and exports of hazardous wastes (according to the Basel Convention)

- Contamination of soil, water, and air, as well as excessive water consumption

- Other significant forms of environmental pollution

LkSG looks to reduce corporate human rights and environmental risks and violations by obligating companies to implement the following supply chain due diligence and compliance procedures:

- Develop and put a supply chain environmental and human rights risk management plan in place

- Assign internal organizational responsibilities for compliance and due diligence activities

- Create a policy statement on the company’s human rights strategy

- Establish grievance mechanisms for workers

- Introduce and implement risk and violation prevention measures within a company's own business operations and in relation to its direct Tier 1 supplier relationships

- Take necessary remedial actions for violations within its business operations and with direct suppliers

- Release a public report that outlines the company's due diligence procedures, key risks, and actions on human rights and environmental issues in the supply chain

- Carry out regular, ongoing risk analyses

And remember, even if your company doesn't do business in Germany or isn't required to comply with LkSG, given that it's one of the most advanced and strict supply chain due diligence laws in the world, it's a good benchmark to aspire to.

Supply Chain Due Diligence: Best Practices

As you likely already know, supply chain due diligence is complex, and requires a holistic view of your suppliers, their processes, plus the ability to track, collect, and connect data at each step. It also involves use of procurement influence to shift suppliers in sustainable directions.

Here are some general best practices for implementing supply chain due diligence programs:

- Identify key suppliers and assess their risks: Identify the key suppliers that are critical to your business and assess their risks, including financial stability, corporate governance, sustainable practices, and operational efficiency

- Establish a process (and cadence) for conducting due diligence: Develop a systematic process for conducting due diligence on suppliers, including defining the scope of due diligence reviews and assessments, identifying the information to be collected, and establishing criteria for evaluating each supplier

- Educate, communicate, and engage with suppliers: Engage with suppliers to understand their operations, business practices, priorities, and any potential risks or issues that may impact your sourcing relationship

- Monitor suppliers on an ongoing basis: Implement a process for ongoing monitoring and evaluation of suppliers to ensure that they continue to meet the company's standards and expectations. Use a combination of education, resources, incentives, encouragement, and potential penalties to promote cooperation and good behavior

- Establish contingency and business continuity plans: Develop contingency plans and a preventative supply chain risk management process in the event of unforseen supply chain disruptions or other supply chain risks

- Collaborate with other supply chain stakeholders: Work closely with other internal and external stakeholders, such as third party standards organizations, regulators, and NGOs, to understand and implement supply chain due diligence best practices

- Pursue continuous improvement: Supply chain sustainability is a long-term, strategic business process. Regularly review and assess the effectiveness of your supply chain due diligence process and make improvements as needed

Conducting supply chain due diligence and gathering all this data can be very time-consuming, particularly in complex, global supply chains, and there may be gaps. Some suppliers may not have a dedicated compliance lead on staff, or know how to measure and track key sustainability KPIs. And your suppliers have their own suppliers and subcontractors. A holistic supply chain due diligence program uses supplier-specific, primary, and third party data where possible, then fills in the gaps with industry averages, benchmarks, and other research.

Need supply chain due diligence support?

Brightest helps hundreds of companies engage suppliers, conduct due diligence, and assess supply chain ESG risks and sustainability performance

Better Supply Chain Transparency and Traceability = Better Due Diligence

As the old saying goes, you can't improve what you don't understand or have the ability to measure. If your company doesn't have a supplier and vendor database or tracking system, you need to work with IT and operations to set one up. Many traditional supply chain management systems, ERPs, and databases aren't designed for sustainability reporting or ESG metrics, so make sure you take that into account, or use a dedicated supply chain carbon accounting system like Brightest.

If your organization's operating at scale, it's likely your supply chain is fairly complex. Apple, for example, works with nearly 1,000 Tier 1 suppliers around the world to manufacture iPhones and Macbooks. However, supply chain due diligence efforts benefit from focus and simplicity, so start by engaging your strategic, long-term Tier 1 suppliers and direct contract relationships. Meet with them about conducting a supplier sustainability survey to gather baseline ESG and sustainability data. Try to understand what they do and don't measure. Educate them on why supply chain sustainability matters to your business and theirs. Help guide them if they don't know how to calculate their emissions or provide you the disclosures you're looking for.

Once you have visibility into your top Tier 1 suppliers, work your way toward better understanding your Tier 2 suppliers and subcontractors. Primary suppliers regularly subcontract to other suppliers and purchasing agents, particularly in retail, apparel, and "fast fashion." Unfortunately, these Tier 2 and Tier 3 suppliers often operate with very little oversight or consideration around worker human rights, workplace safety, or the environment, which makes Tier 2+ supply chain due diligence just as critical as Tier 1.

Your ultimate output should be a sustainability or ESG "scorecard" and due diligence checklist for each supplier. Once your company knows where its supply chain issues and gaps are, you can set goals, implement supplier programs, work to influence existing partners, and consider establishing new relationships with more sustainable ones.

Supply Chain Due Diligence in Action with Brightest

"Using the Brightest platform and tools, we can now identify our suppliers' ESG strengths, gaps, challenges, and opportunities we can collaborate on. As we move into 2023, Brightest is helping us define measurable short-term and long-term action plans to empower a more sustainable Outerstuff"

- Nathan Fleisig, Director of CSR and ESG

You have to start somewhere, and we've seen dozens of major global brands (and some of the world's largest procurement organizations) increase their focus and investments in supply chain sustainability, traceability, and due diligence further in 2022 and 2023, including Amazon, Apple, Disney, Nike, Target, Walmart, and many others. We expect this trend to continue and broaden in the coming years, influencing more upstream suppliers and partners to comply with better ESG standards and labor practices.

Your Next Steps with Supply Chain Due Diligence

Remember, this work is challenging, and most organizations are undertaking it right now. In a recent survey by The Sustainability Consortium, a non-profit dedicated to improving the sustainability of consumer products, less than 20% of the 1,700 respondents said they have a comprehensive view of their supply chains' sustainability performance. More than half reported being unable to determine top sustainability issues within their supply chain. That all starts with due diligence.

Despite these difficulties, in most industries, supply chain due diligence is one of the most material paths to proactively managing supplier risk(s) and reducing your own organization's environmental footprint. Your supply chain is the foundation for your organization's sustainability performance and GHG emissions inventory, and it can't be overlooked.

Engineering and management a safe, sustainable, and global supply chain is complex, and requires internal capacity, resources, investment, and, most of all, time. But, when done well, supply chain leadership boosts everything from local community benefit to your firm's brand, reputation, operating financials, and investor consideration.